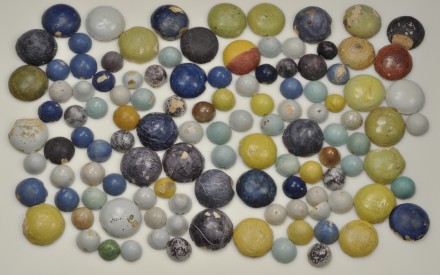

For a long time, the most important ingredient of porcelain, kaolin – also known as China clay – was not available in Europe. But clay containing kaolin was found in Staffordshire (England) in the 18th century. English potters used it to make ‘creamware’, a cream-coloured earthenware with a transparent glaze. Creamware is harder and more robust than lead-glazed or tin-glazed earthenware.

In 1759, the famous English pottery manufacturer Josiah Wedgwood established a factory at Burslem to manufacture creamware. English creamware became extraordinarily popular in the Netherlands, and was already being imported in large quantities in the 18th century. It satisfied the demand for cheap, fashionable tableware and therefore became a formidable competitor for Dutch delftware even in the eighteenth century. In Germany creamware is known as Steingut, and in France as faience fine.

Regout

Continental potteries, helped by English experts, started to produce imitations of the popular Wedgwood. In the Netherlands, the first to do this – from 1836 – was Petrus Regout in Maastricht. In the early nineteenth century, De Porceleyne Fles in Delft also began making a type of creamware. After Joost Thooft became the company’s proprietor in 1876, it developed its creamware further, turning it into an extremely hard, brilliant white earthenware closely resembling porcelain.

Creamware was very popular as it was both cheap and fashionable

Creamware was fired at approximately 1100 degrees Celsius. After the object was decorated another layer of transparent glaze would be added. The decoration was originally handpainted, until the introduction of transfer printing around 1750. This technique involves transferring to the pot a design printed on prepared paper using the copper engraving technique. Once a layer of transparent glaze had been applied, the object would be fired again.

Add new comment

Only logged in users can post comments

Log in or register to post comments